Select a Category

Upgrade your SR20 and SR22 brake system with APS!

CNC machined from a one-piece forging. When the metal is forged, it creates a directional grain flow that follows the contour of the disc. This creates a stronger disc with reduced risk of the cracking and catastrophic failures.

The APS proprietary heat treatment strengthens the steel and cannot wear off. This heat treatment gives the steel its black appearance and provides the surface with a high resistance to the corrosion and oxidation associated with the extreme thermal cycling experienced in aircraft braking systems.

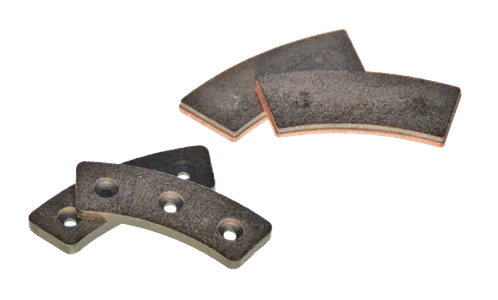

Two types of brake linings are available: semi-metallic/organic (abrasive) and metallic (adherent). Semi-metallic linings are made with Kevlar fibers integrated into the material, providing the greatest stopping power and long lining life. The optimal operating temperature of the semi-metallic linings is 600-900 deg F. The main ingredient in the metallic linings is iron. In an adherent system, a thin layer of lining material transfers and adheres to the disc during break-in. The optimal operating temperature range of the metallic linings is 950-1200 deg F.

Use P/N APS66-06200 for SR22. Use P/N APS66-10500 for SR20. Confirm your serial number range.