Natural Composite Propellers

Light-weight

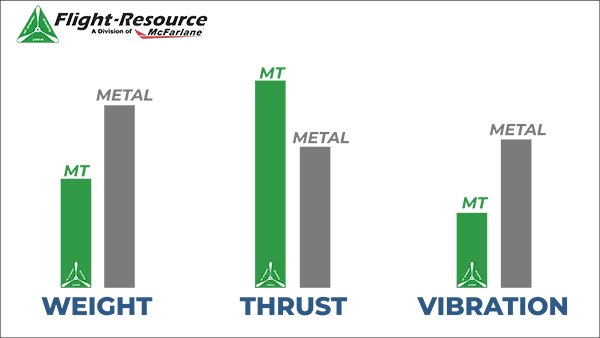

MT Natural Composite Propellers are significantly lighter than aluminum propeller systems. This saves weight where it is most important, on the end of your engine crankshaft.

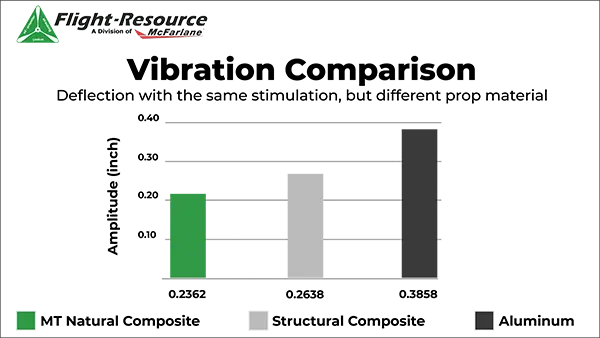

Vibration dampening behavior

Due to the unbeaten vibration behavior no ground rpm limitation and in flight rpm limitation must be established for certified MT-Propeller installations using the natural composite design. Aluminum supports harmonic vibration. Composite does not. Gyros, motor mounts, radios, heat muffs, cowlings will have a longer life as a result of the reduced vibration.

Superior strength

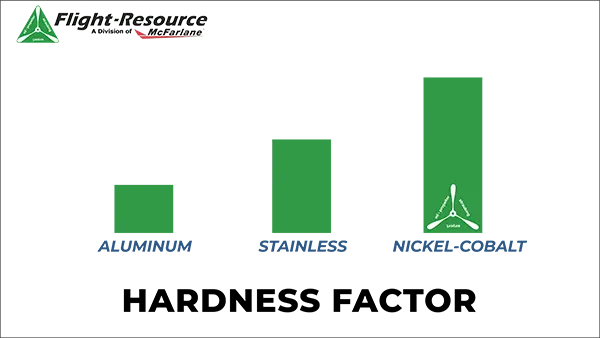

These are the same natural composite blades and hub that are used in our Unlimited Aerobatic Propeller Series. We also use stainless steel and Nickel-Colbalt instead of aluminum on the leading edge guard resulting in superior strength, durability, and erosion protection.

Unlimited blade life

Metal props have absolute dimension limits. Every time you have a nick filed out and the prop dressed, you get closer to that limit. At some point it will exceed the use tolerances and must be scrapped. In addition, each time a metal prop is dressed, you will change the optimized performance dimensions established by the manufacturer. MT Propellers, when overhauled, are brought back to exact factory new dimensions.

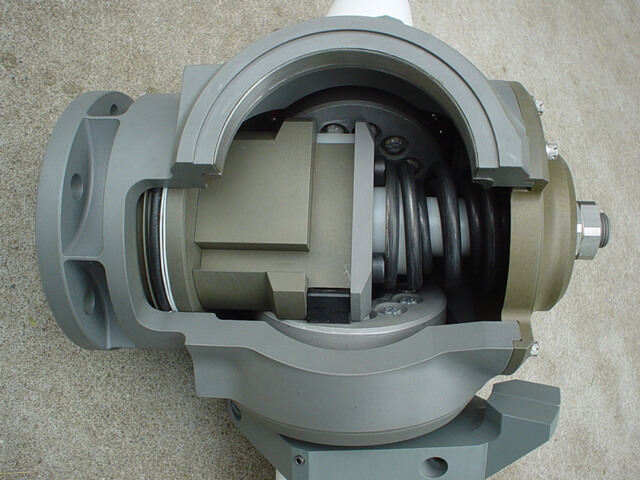

Steel hub inserts

MT Propeller hubs use a steel bearing insert that is replaceable. Standard hubs wear against the machined aluminum and must be completely replaced when exceeding the tolerances.

|

|

|

Significant noise reduction

3 blade conversions result in smaller diameter compared to 2-blade installations. Shorter blades run quieter than long blades due to the lower tip speeds. Another advantage of lower tip speeds is the maintenance of smooth airflow across the blades. This results in more lift/thrust.

Less drag

A smaller prop arc disk has less drag than a larger diameter prop arc discs.

More Ground Clearance – A smaller diameter of the propeller installation will provide less chance of prop damage from objects picked up from the ground.

Adds resale value

Like air conditioning in a car, you get to enjoy the benefits while it is yours, then get back what you paid for it in the future.

Easy installation

Simply bolt it on. Uses existing prop governor.

Full warranty

1 year or 1000 hours (which ever occurs first) for any manufacturing defects.

Choice of colors

White, Black or Grey. Custom colors available with small up-charge.

To find the right MT Prop for your aircraft, call our Propeller Specialists at 866-717-1117 or go to Propellers to learn more.

MT-Propeller Blades – Key Features

- 2” wide Durable Nickel Cobalt Leading Edge. Widest leading edge on turboprop blades for best erosion protection.

- A lightning strike does not make the blade unserviceable compared to structure composite blade, because the MT-blade is not conductive.

- Structural composite blades lose their lightning protection after one impact and must be retired.

- After a ground strike the MT-Propeller single piece hub can be overhauled.

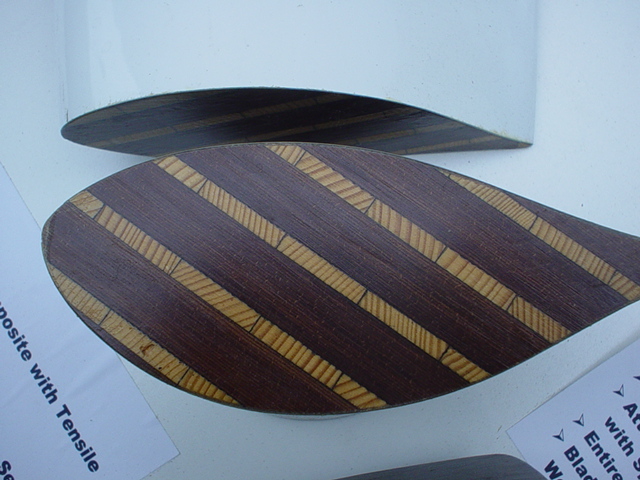

MT composite vs. structural composite blades

Aerospace grade carbon fiber combined with highly compressed beech/spruce wood core has a higher strength than aerospace aluminum with no corrosion and fatigue limit.

The MT-blade has no spar for the load carrying core. FOD on leading edge or trailing edge as well as the blade mid area does not result in structural damage requiring the replacement of a blade. MT-Propeller natural composite blades are certified for unlimited life and can be repaired in the field or at overhaul shops worldwide.

Deice Boots are available on structural composite blades. The boots are integrated into the airfoil to keep the original shape. No extra drag from Deicing is created on MT Turboprop blades.