Shimmy Dampener Assembly for Cessna Aircraft

Fully repairable, self lubricating, and 5x more dampening power than the Lord throw-away rubber dampener!

P/N MC0442512-1 for Cessna 150, 152, 172, 175 and 182 Aircraft

McFarlane Shimmy Dampener Compared to Lord

Direct replacement for part numbers 0442512-1 and 0542119-1.

It's everything the original should have been and more than the rubber units ever could be!!

Improved design for consistent dampening action!

- Oversize shaft for rigid strength

- Wear resistant hard anodized housing

- Costs less than the throw away rubber dampener

- Temperature/altitude compensated hydraulics for low maintenance

- Fluid level can be checked on the aircraft

- Go years without Servicing!

Temperature compensated hydraulics

- Almost no service required

- Even the first minor movements are dampened

- Consistent dampening action

- No oil leaks

Seal Kit P/N SDKT-7

- Designed specifically to re-seal McFarlane shimmy dampeners

- Contains all required O-rings and back up rings

To repair your fluid dampener, go to Seal and Repair Kits.

For dampener replacement parts, go to Shimmy Dampener Components.

|

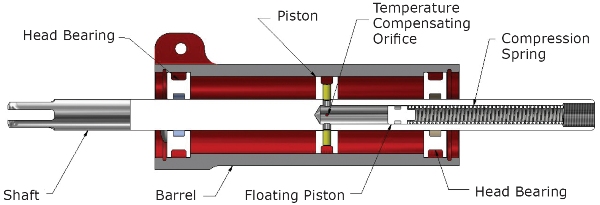

What Does Temperature Compensated Mean? By Dave McFarlane

When hydraulic oil changes temperature, the volume of the oil also changes. This volume change from a temperature reduction will create a vacuum in the oil chamber of the original Cessna uncompensated shimmy dampener. This vacuum will cause the oil to vaporize giving the oil a foamy expanded mixture that is compressible. The shimmy dampener action is then drastically degraded. An increase in temperature will increase the oil volume causing a drastic pressurization of the dampener oil chamber. This pressure will force small quantities of oil past the dampener shaft seals. The decrease in oil will then aggravate any temperature reduction with increased chamber vacuum and related oil vaporization. This process explains why continuous servicing of the original shimmy dampener is required.

The temperature compensation system works by having a small chamber of oil that is spring pressurized through a very small passage into the main dampening restrictive orifice of the shimmy dampener. The spring loaded oil chamber can adjust for oil volume changes as temperature changes. A similar system is built into your car shock absorbers. The temperature compensated hydraulic system requires very little service over extended periods of time and assures stable shimmy dampening action. Hundreds $$ less than Lord throw away dampener! |

|

Why is a hydraulic shimmy dampener better than a rubber dampener? By Dave McFarlane

A rubber based dampener is continuously fatiguing the rubber components as it changes direction of motion. The rubber system depends on stable friction of the rubber riding in a metal tube. This is very difficult to achieve over extended usage. There are inherent differences in static friction of rubber and dynamic friction of rubber that affect dampening performance. Long term use changes the performance of the dampener caused by all of these un-repairable factors. The hydraulic system works in a film oil with stable performance for long periods of time and it is totally repairable.

McFarlane Shimmy Dampener Compared to Lord - 5x the dampening power! |

P/N MC0442512-1 installed on a 152: