Select a Category

Improved design for consistent dampening action!

Temperature compensated hydraulics

General Discussion - The McFarlane shimmy dampener is designed to drastically outperform the Lord® brand rubber dampener and the original Cessna hydraulic shimmy dampeners. All the dampening forces of the McFarlane dampener were found similar to the original vintage Cessna hydraulic dampeners. Our improved dampener extends the life, offers greater consistency of dampening forces, and reduces the required servicing frequency as compared to the Cessna dampener. Tests were performed and carefully measured on a new McFarlane dampener, a new Cessna hydraulic dampener, and a new Lord rubber dampener. The Cessna hydraulic dampener was found to have similar dampening characteristics as the new McFarlane hydraulic dampener. For simplicity, only the McFarlane hydraulic dampener results are shown in the data charts.

What Would the Ideal Dampener Do? The best possible dampener would move easily with no resistance to motion at slow speeds for quick and easy control of the nose wheel while steering the aircraft and the dampener would have tremendous resistance to motion when moved at high speeds during shimmy. The aircraft steering system uses spring pressure to turn the nose wheel. If the dampener is hard to move while steering, the steering input of the pilot is absorbed by the steering springs and no steering occurs. The result is that the nose wheel does not respond or responds slowly and more erratically to pilot input. The less force required to move the dampener at slow speeds the better steering control the pilot has. Nose wheel shimmy creates high speed movement of the dampener. Shimmy is prevented or stopped by high dampener resistance to motion. The higher the force required to move the dampener at shimmy speeds the better the dampener will stop shimmy. It is desirable to have the dampener forces increase as the speed of the shimmy cycle increases. The ideal dampener would also have heavy dampening forces for a large portion of the shimmy travel cycle. Good shimmy dampening characteristics would be a combination of strong dampening forces and a long motion cycle for the dampening forces.

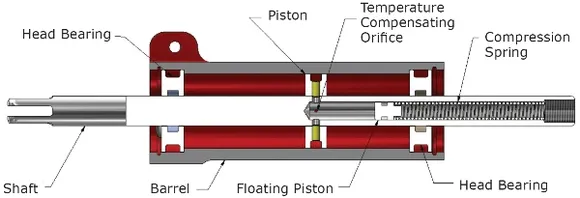

How Does a Hydraulic Resistance Dampener Work? In general, the hydraulic shimmy dampener design depends on oil flow through a controlled orifice (several small holes in the piston or clearance between the piston and cylinder wall or both). Since the orifice or clearance is a fixed size there is more resistance to the oil flow the faster the dampener is moved. The oil path is designed to be large enough that when the oil is moving slowly while steering it can flow easily through the allowed space from one side of the piston to the other. When the oil is moving fast, the oil path is too small to let higher volume of oil through quickly. The faster the shimmy dampener moves the more resistance there is to oil flow. As the dampener action becomes faster, the dampening forces increase. Since dampening forces are related to the speed of the oil flowing through the orifice, there is high dampening forces for all of its travel cycle except when it is changing directions. Restricted flow hydraulics makes the perfect shimmy dampener system.

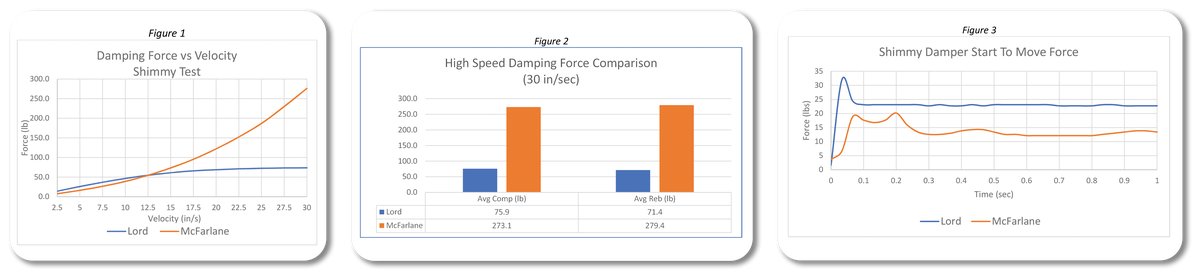

How Does a Lord® Friction Type Rubber Dampener Work? The Lord® rubber dampener depends on the friction of the rubber piston against the cylinder wall. Rubber by nature requires a lot more force to start it to move (static friction) than the force required when it is in motion (dynamic friction). By characteristic of rubber sliding on metal, there is little difference in the friction forces when a rubber piston is moved slowly in the cylinder or if it move fast in the cylinder. The friction can actually decrease with the speed of the rubber piston. The Lord® rubber piston is designed where the rubber expands during the change of direction adding more friction that gives it its dampening action. The problem is that as the rubber piston moves back and forth there is increased friction only at the direction change position which is a very small part of the motion cycle. The friction forces during the rest of the shimmy motion cycle is close to the low slow motion (steering) friction forces. The change of direction is only a short part of the travel cycle. With the Lord® dampener, there is a diminishing gain of the dampening action as the speed increases. See Figures 1 and 2.

How Does the Service Life Compare? The service life of the different dampeners was tested by cycle testing a new vintage Cessna hydraulic dampener, a new McFarlane dampener and a new Lord® dampener. The Cessna hydraulic dampener failed at approximately 17,000 cycles with the O rings leaking and with significant wear in the head bearing. The McFarlane dampener went over 300,000 cycles without seal failure or any significant wear in the head bearings and did not fail. The Lord dampener also went over 300,000 cycles without a failure. The Cessna hydraulic dampener wears out the head bearing area and that allows the piston to shift out of position resulting in scratches and grooves in the cylinder wall and piston. The Cessna hydraulic dampener is repairable but generally comes up a little short of new performance after rebuild due to the cylinder wall scratches and groves that remain. The new McFarlane dampener is designed with an o-ring seal between the piston and cylinder. The o-ring and a heavier head bearing along with hard anodizing prevents piston and cylinder wall scratching and grooving. The improvements allow the McFarlane dampener to be economically rebuilt many times to original performance. The Lord® dampener does not have a repair and must be thrown away when they fail to prevent shimmy.